Leading UK book printer, Bell & Bain, has continued its investment in digital book production with Europe’s first Horizon Smart Binding System supplied by Intelligent Finishing Systems.

The move follows the recent successful addition of a Fujifilm JetPress 540W colour inkjet web press which has helped the company secure substantial growth in both digital and traditional offset printed books.

After very careful evaluation of all the leading manufacturers, Bell & Bain replaced an existing Muller Martini Sigma binding line with the Horizon Smart Binding System.

Managing Director Stephen Docherty explains: “After first seeing the Horizon Smart Binding System at an exhibition earlier this year, I was completely blown away by the very high quality book binding being produced. It was simply the best binding quality that I have ever seen and the performance of the inline variable three-knife trimmer producing different format size books was truly phenomenal.”

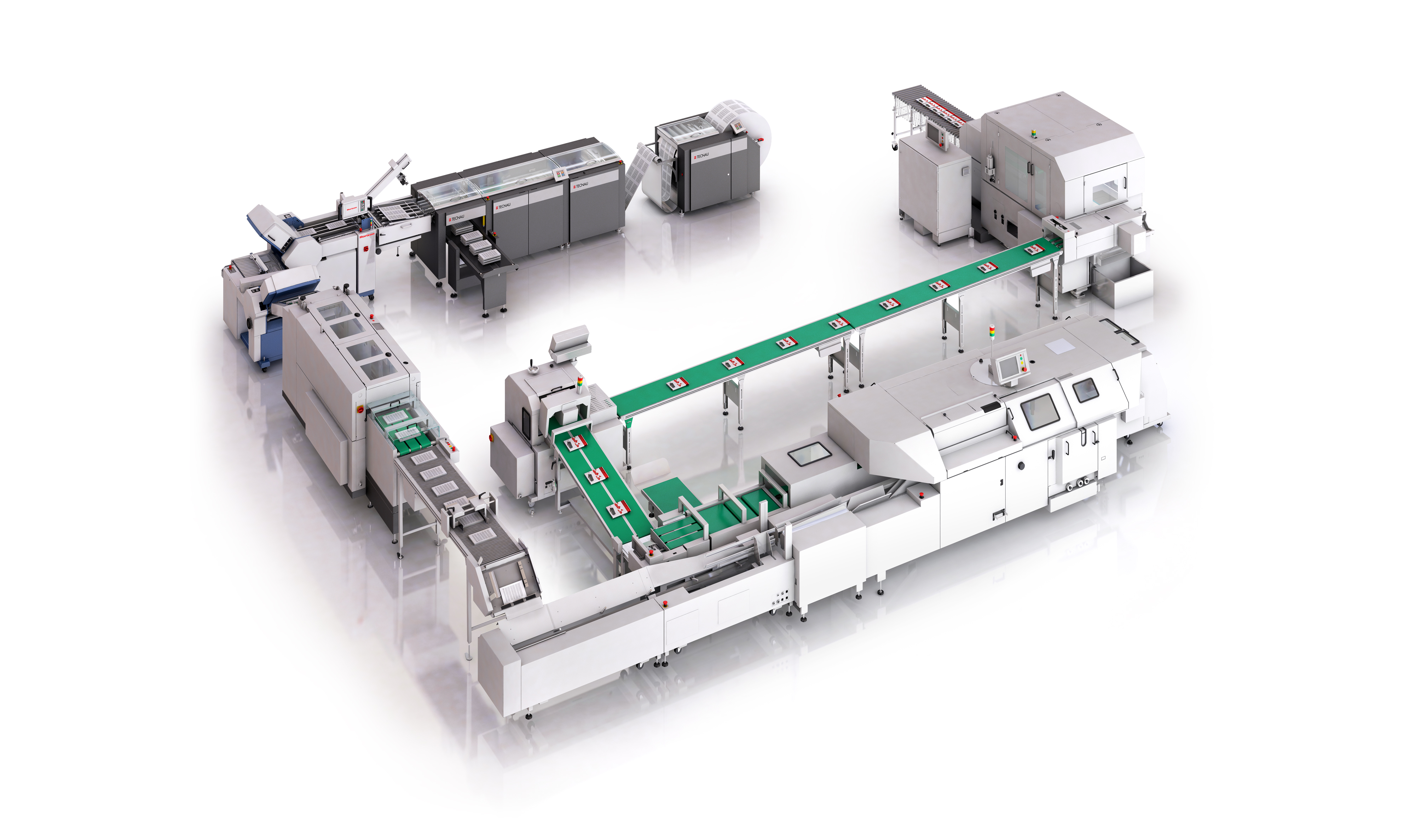

The Horizon Smart Binding System is modular in design and has been configured with a Tecnau 530 buffer, c20 cutter, s20 stacker and 568 feeder for configuration inline to their Fujifilm JetPress 540W.

Technical Sales Director for IFS Jason Seaber says: “This white paper solution will enable Bell & Bain to go from paper rolls to finished perfect bound books of very high quality with variable format size and variable book thickness. This high speed system sets a new standard in short to medium run digital mono and colour book production. Optional Horizon Signature Gatherers can also be added to this system to also process offset printed signatures at binding speeds up to 4,000 books per hour.”

The Horizon Smart Binding System consists of four key elements; signature folding, stacking with pre-gluing of each book block, variable perfect binding with automatic cover and book block matching and variable three-knife trimming by dynamically reading a barcode on every book cover. For even more production flexibility, cut-sheet stacked output is enabled by the Tecnau c20 cutter, s20 stacker for other products and digital sheet input to the Smart Binding System is also possible by using the feed table and automatic feeder on the signature folder. The signature folder can be quickly changed from inline to near-line.

Installation begins next month at Bell & Bain’s new digital book factory in Lawmoor Street, Glasgow. All the Horizon and Tecnau machinery within this customised solution will be supplied and fully supported by IFS.