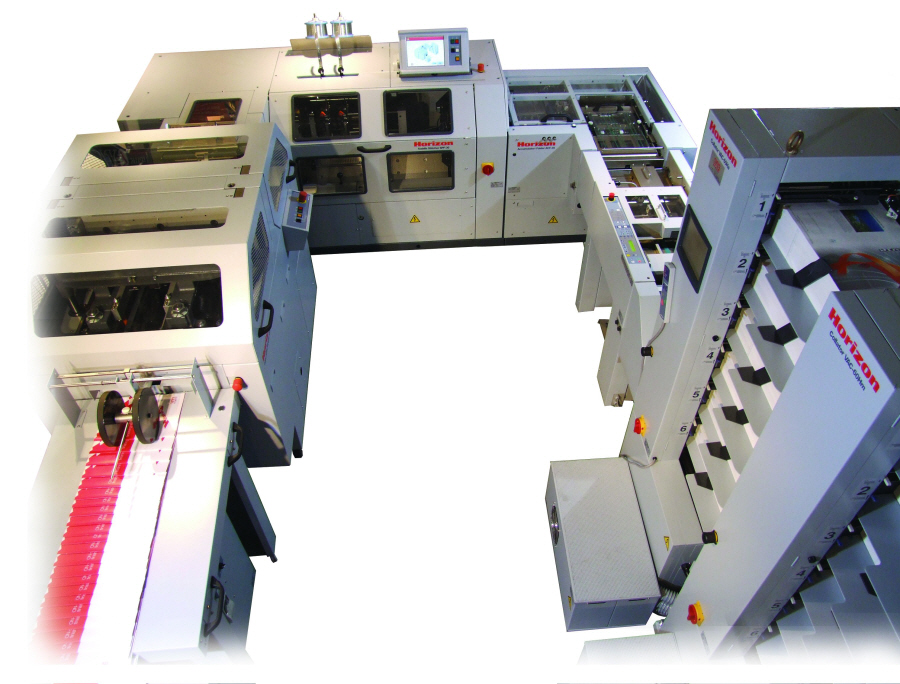

Lithgo Press has created a more flexible bindery with investment in an Intelligent Finishing Systems’ supplied Horizon StitchLiner 5500 with three VAC-1000 tower collators.

The Leicester specialist in high quality luxury print picked the fully-automated Horizon StitchLiner 5500 to handle a wider range of run lengths.

Explains managing director Mike Atkinson: “We also have a Heidelberg ST300 but with both systems we can now choose quite late in the day which one to use. As the StitchLiner is quick and easy to set up it is perfect for short runs but its quality and robustness means it can also handle longer runs too.

“It gives us as much flexibility as possible and has opened up capacity. Previously jobs would have taken quite a bit longer to complete. This also enables us to be more cost competitive.”

Lithgo’s StitchLiner features a high definition icon-based colour touchscreen for set-ups in less than two minutes. It can work from flat four-page sections, eliminating the need for separate bindery stages to be undertaken such as signature folding and creasing. Its integral ACF-30 Accumulator with scoring, plow-folding and heavy-duty HTS-30S Three-Knife Trimmer means there is no need to pre-fold into signatures or pre-cut sections top and tail – resulting in significant time, waste and energy savings.

“We liked the StitchLiner because it takes sheets that were planned in a such a way that they could be traditionally folded,” says Atkinson. “That means we can plan work with traditionally folded sections. We looked at other solutions but they didn’t do that.”

He adds: “We are not compromised on quality and at the end of the day we have got options.”

The system includes three Horizon VAC-1000s with flexible but powerful programming and user-friendly operation. Says Atkinson: “We chose the three towers specifically with a long run collating job in mind. We have since completed that and it handled the few million sheets easily. That allowed us to keep the work in house. I also wanted to be able to collate the job in two sets not three sets and that worked very well.”

He concludes: “The new StitchLiner has been a great addition. It gives us options in production to get jobs out of the door quicker, more easily and cost effectively. With the investment we will be able to do that for a long time to come.”