Essex printer and publisher Maypole Press’s Horizon StitchLiner from IFS has been improving the bottomline since it was installed. It has also streamlined workflow and increased production speeds.

“It has been paying for itself since day one,” explains Dean Robinson, Print Manager of Maypole Press: “There a couple of jobs alone that will cover the cost of the investment over the year.”

Maypole Press produces general commercial print and publishes and prints full colour, glossy, local community magazines including the South Woodham Focus, Burnham Focus, Danbury Journal and Ingatestone Journal. The operation runs a four-colour Ryobi 784E, a Konica Minolta Bizhub and a Roland wide format press.

It was not ROI that prompted the decision to invest comments Mr Robinson: “We had an older Duplo system and it was time to upgrade. We saw the StitchLiner in operation at Print Efficiently and then we went to see it at an IFS customer. We liked the robust build and the fact you can adjust the thickness of the book to give a nice tight fold.

“The good quality collators aid production and workflow, the trimmer gives a neater edge and the whole system is easy to set up and run. I even set it up the other day following prompts on the touch screen. There is no downtime and we no longer have any bottlenecks.

“It is a necessity,” he adds “We couldn’t do without it. We have one weekly job that is about 8,000 A4 magazine averaging 32pp and we completed it in half the time. Many of our jobs are short runs. We can interrupt longer runs on the StitchLiner but because it finishes the work so quickly we don’t need to do that very often.”

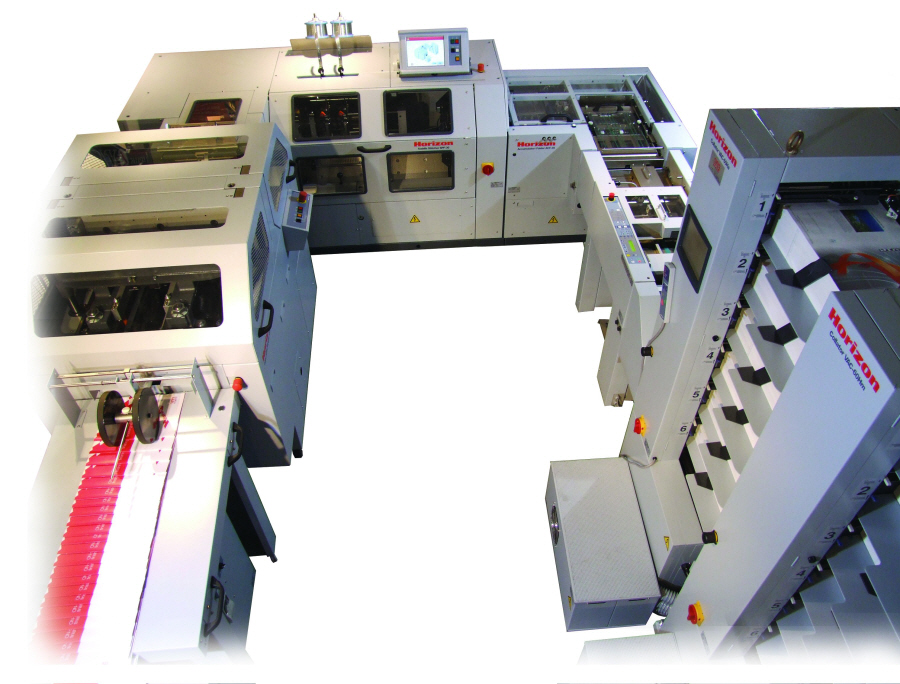

The fully-automated 11,000bph Horizon StitchLiner includes a high profile icon-based colour touchscreen for set-ups in less than two minutes. The key to the StitchLiner’s enduring popularity is its ability to work from flat four-page section, eliminating the need for separate bindery stages to be undertaken. Its integral three-knife trimming station means there is no need to pre-fold into signatures or pre-trim top and tail – resulting in significant time, waste and energy savings