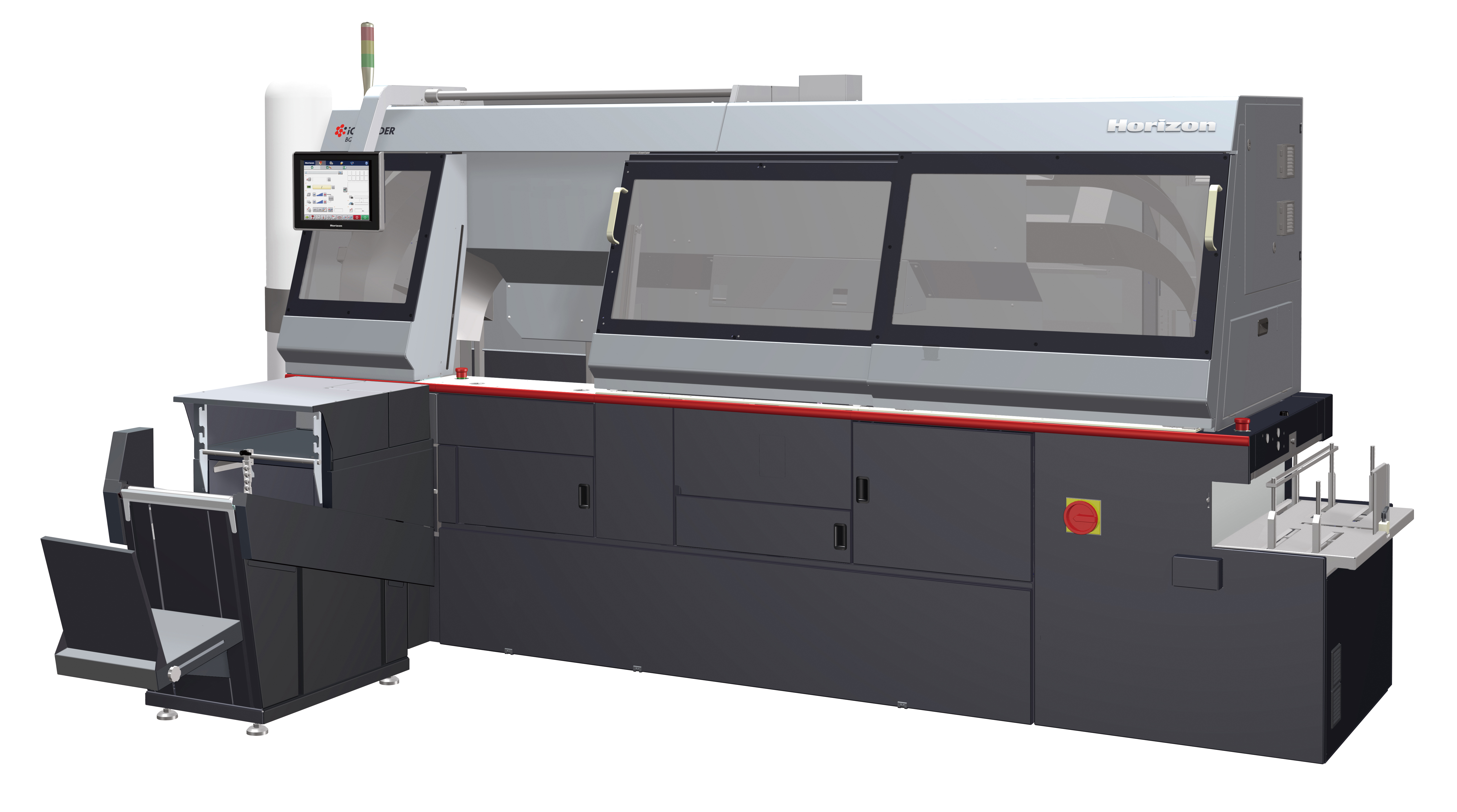

The new Horizon BQ-500 four clamp perfect binder responsively supports a broader range of run lengths thanks to its unique combination of productivity, efficiency and operator friendly features.

Building on the successful tried and trusted features of its BQ-470 and BQ-480 predecessors, the BQ-500’s enhanced functionality includes:

- Smoother faster more highly automated set up via a large 12.1 inch colour touchscreen.

- 21 automated sections from cycle and milling speed to roller height and guide positioning.

- Memory storage of up to 999 jobs.

- Pre-installed variable software capability.

- Variable thickness production of 5mm up to 800bph.

With a sharper focus on social distancing and reduced operator touchpoints the Horizon BQ-500 has a number of new design features that aid easy operation.

They include a status light that indicates, at a distance, how the binder is running, and an ergonomic design where all the operator required actions are on the same side.

The new system is also one of the first to be pre-installed with Horizon’s cloud-based iCE LiNK workflow. It provides access to an intuitive easy to use dashboard that reports real-time production analysis for improved efficiency and profitability, remote update capabilities and scheduled maintenance resulting in less downtime. The information is accessible via smartphone, tablet or desktop PC and the software is designed for integration with MIS systems.

“This latest evolution of Horizon’s highly successful series of four clamp binders elevates automation and ease of use to new levels supporting greater productivity and efficiency,” says Eric Keane, IFS Managing Director. “Horizon’s team of engineers have reviewed and enhanced every element of the system from job input to delivery. Among the improvements are deeper scoring for a thicker cover, a new gluing mechanism, glue overflow detection, a faster nipping changeover and a switchable exit mechanism for thick book or PUR book production. The powerful combination offers any bindery a futureproof system for high quality and versatile service delivery.”

The BQ-500 is available now.